Manufacturing Process Management

Manufacturing involves the production of entirely new products from raw materials or components. It’s the process of designing, developing, and assembling products from scratch.

New G Solution system provides end-to-end control over the manufacturing lifecycle that empowers businesses to seamlessly plan and manage production processes, monitor inventory levels, and streamline resource allocation.

Whether it’s for assembling complex products with precision or efficiently breaking them down for recycling, New G Solution’s manufacturing features empower you with the tools needed to streamline processes, reduce waste, and uphold sustainability practices.

With New G Solution, you can confidently track every aspect of your manufacturing operations, from component procurement to final product assembly. Our comprehensive platform seamlessly integrates component quantities and costs into the finished product, providing you with a clear and transparent view of your production expenses.

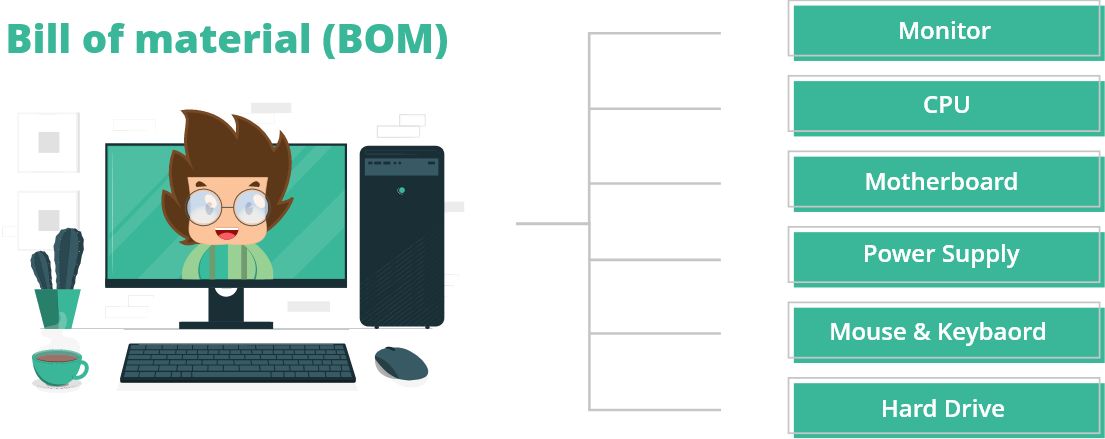

Bill of Materials (BOM) Management

Our ERP system excels in BOM management, allowing you to create, modify, and maintain detailed BOMs for each product variant. Seamlessly track hierarchical relationships among components, sub-assemblies, and raw materials. Easily input quantities, descriptions, and specifications, serving as a reference for procurement, assembly, and inventory management. The BOM ensures accurate production and helps with cost estimation, planning, and quality control.

Forecasting

Optimize your Manufacturing Process Management with New G Solution’s intelligent forecasting capabilities. Our advanced system analyzes available quantities and existing manufacturing orders to accurately predict the products and components that require ordering. Stay informed and make proactive procurement decisions with New G Solution’s accurate forecasting feature.

Refurbishing Workflow Management

Refurbishing involves the process of restoring, repairing, or improving existing products to a like-new condition. It’s often done with electronics, appliances, and other items that can be revitalized.

We’ve developed comprehensive features to facilitate efficient and effective refurbishing processes. Our goal is to streamline every aspect of the refurbishing workflow, from receiving used products till you get the final products, you can track the status of the refurbishment process, ensuring that each refurbished product meets the highest standards.

With our ERP system, you can efficiently manage component replacement and repair tasks, update inventory records, adjust pricing for refurbished items.

Whether you’re dealing with electronics, appliances, or other refurbishable items, our ERP system’s refurbishing features support you in delivering high-quality, like-new products to the market as well as an efficient fulfillment and shipping.