Forecasting Your Inventory, How To Do It? Techniques and Tools

Small Business

LAST UPDATE: JUL 27, 2022

10 minutes reading

What Is Inventory Demand Forecasting?

The procedure of estimating the quantity of inventory expected to accomplish upcoming client requests is known as inventory forecasting. This estimate is based on the anticipated volume of inventory that a company will sell during a specific time. This projection is created using sales data and upcoming promotions.

Inventory forecasting, commonly known as inventory planning, seems to be a crucial component of inventory management. It seeks to make sure businesses have just enough inventory to meet upcoming orders without going overstock.

By setting accurate forecasting, companies may meet client requests with the minimum amount of inventory and maximize cash flow that allowing you to decrease your inventory costs. Setting a reorder point is only one aspect of forecasting; data analysis is used to find patterns and trends that can be used to meet changing client demands. reorder points are a crucial component, but inventory forecasting involves much more.

When Should You Do It?

Inventory forecasting is essential to your company’s financial performance, regardless of whether you manage an eCommerce website or are stocking a physical store.

when you lose out on sales because of too little level of inventory or stock your stores with too much inventory, you freeze up money that could be utilized to expand your company in other ways.

Applying inventory forecasting methods will enable all of these scenarios to be resolved, ensure a secure stock level, and accurately forecast future demand which can be accomplished by minimizing your stockouts, and preventing lost sales revenue. With this knowledge, you may decide how many units to order and when to refill, another thing to be done is to decrease your inventory holding expenses, by ordering exactly what you require and keeping only those items on hand, as opposed to ordering too many, you may better manage your inventory storage space. As a result, less unnecessary storage space is needed and associated expenses are lower.

Inventory Forecasting Formulas:

Even though inventory forecasting typically involves human decisions, it’s unquestionably not a game of making educated guesses about when to restock.

To help you make informed decisions about your inventory and have the demand forecasting benefits, this section will discuss three formulas for inventory forecasting with examples.

-

Lead Time Demand

The lead time is the number of days it takes you to get the products after purchasing an item with your supplier. Or to put it another way, it’s the time you need to restock.

This inventory forecasting formula indicates the quantity of demand during this time.

You may determine how much inventory you need to have by calculating the lead time demand, which will help you avoid stockouts as you wait for fresh stock.

We define the lead time demand inventory forecasting formula by:

Lead time demand = (Average lead time x Average each day sales).

The example that follows shows how to use this tool.

Example:

Using your fancy clothing store as an example. You know the following details about one of the most popular trench coats:

20 days maximum lead time

8 days is the minimum lead time.

12 pieces maximum daily sales

6 pieces minimum daily sales

A few working drafts must be completed before moving on to calculate the lead time demand:

(20 + 8) / 2 = 14 days is the average lead time.

Daily sales on average equal (12 + 6) / 2 = 9 units.

This trench coat’s lead time demand = 14 x 9 = 126

This inventory forecasting formula implies that while you wait for a new supply from your supplier, you’ll need to have at least 126 units of this coat on hand.

If not, there’s a chance you won’t have adequate stock to complete consumer orders during this time.

-

Safety Stock

Safety stock, commonly referred to as minimum stock level, is the volume of excess stock you maintain on hand in case demand changes or unanticipated events occur. Keeping safety stock reduces the likelihood of a stockout and aids in determining whether to place another purchase.

The safety stock inventory forecasting formula can be defined by:

Safety stock= (Maximum each day sales x Maximum lead time) − (Average each day sales x Average lead time).

The following details are related to a ring that was purchased from your jewelry store, for instance.

Example:

5 pieces maximum each day sales.

1 piece minimum each day sales.

11 days maximum lead time.

7-day minimum lead time.

The following are the computation’s current working drafts:

Daily sales on average equal (5 + 1) / 2 = 3 units.

(11 + 7) / 2 = 9 days is the average lead time.

Calculating the ring’s safety stock = (5 x 11) – (3 x 9) = 28

You should always keep at least 28 of these rings on hand in case this situation arises.

-

Reorder Point

The term “reorder point” (ROP) identifies the precise stock level at which inventory needs to be reordered.

It’s time for you to place an order with your suppliers once your stock falls underneath the reorder point or meets that level.

reorder point inventory forecasting formula can be defined by:

Reorder point = (Average each day sales x Lead time) + Safety stock.

The reorder point could be chosen even without safety stock, depending on your sort of market and customer behavior.

The formula for determining the reorder point is as follows, providing you don’t choose to take safety stock into account while making reorder decisions:

Reorder point = Average each day sales x Lead time

Example:

This data refers to a guidebook you sell at your store.

22 pieces maximum daily sales

14 pieces minimum daily sales

Lead: two days

30 safety stock

To calculate the reorder point, you first should determine the average daily sales:

Average daily sales are equal to 18 units (22 + 14 / 2).

So, for this particular book, the ordering point = (18 x 2) + 30= 66

It implies that you will need to restock the guidebook once the stock level reaches 66 or less.

Inventory Forecasting Methods:

Meeting customer demand is, as we have stated, the ultimate purpose of inventory forecasting. So let’s continue by going over the methods for predicting demand.

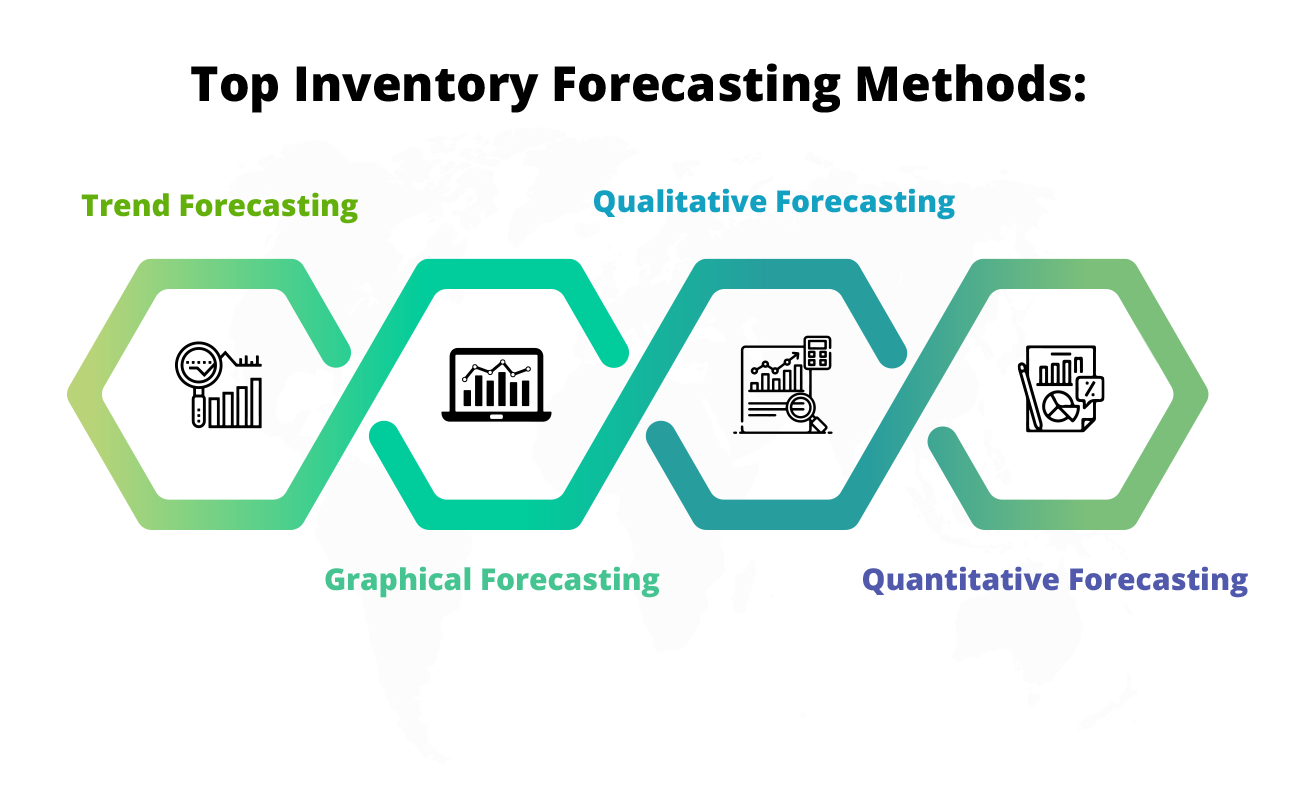

we will discuss the four most popular inventory forecasting methods, which can be used separately or in combination to produce a more thorough outcome, and ensure a powerful order management system.

Trend Forecasting

Using trend patterns, this inventory demand forecasting method forecasts future inventory demand. Assessing the potential of your products, customers’ demands, and potential cultural changes, forecasting inventory based on sales, and current purchase habits.

You can evaluate how much inventory you’ll need by predicting how many stocks to sell. Accordingly, it relies on the forecast’s upward and downward slopes. The results of your trend projection may also drive additional studies to enhance inventory forecasting methods.

Graphical Forecasting

You may examine sales patterns more efficiently and visually by converting the sales data into a graphical format because inventory forecasting methods are simpler to understand. You could quite be made this possible by using the troughs and crests to detect prior inventory exploration, trends, and patterns.

Qualitative Forecasting

Qualitative techniques can be considered as one of the most accurate inventory forecasting methods, which offers a far more individualized perspective on the market dynamics at work in your company, but they frequently provide more insightful results. This approach relies more on educated predictions based on experience and market expertise. You can determine when demand trends are ready to change by paying attention to the human component of the market.

Quantitative

Qualitative inventory forecasting methods offer a far more individualized perspective on the market dynamics at work in your company, but they frequently offer more insightful results. This approach relies more on educated estimates derived from experience and understanding of how the market operates. You can determine when demand trends are ready to change by observing the human component of the market.

Useful Techniques To Forecast Your Inventory:

Techniques for inventory demand forecasting can be as simple or as complicated as you choose. Additionally, a corporation can employ a variety of techniques that combine qualitative forecasting with quantitative forecasting (using past demand data) (based on more subjective opinions and insights).

Because corporations do not consider the wide diversity of market demands being observed by their stock goods, many organizations have problems with their basic demand forecasting approaches. Additionally, they ignore to use of inventory forecasting tools to define outside market forces that influence demand volatility.

Here are our top three inventory demand forecasting techniques to allow you to manage your inventory more effectively:

-

Including Demand Trends

As trends change, new technology plays the role of older ones, and social economic, and legal concerns dynamic condition, the demand for the products in your inventory will change rapidly.

As items progress through the life product cycle, they will also follow trends in demand. For instance, the demand curve will be upward during the growth period whereas the tendency will be down during the declining stage.

Keep an eye out for these developments in your demand data and make the necessary adjustments to your inventory projections, and also adapt your techniques by forecasting inventory based on sales. If products are following a certain trend, there is no purpose in making a prediction based only on your base demand.

-

Understand Demand Forecasting Accuracy

You shouldn’t expect your inventory demand forecasting to be entirely correct. Therefore, you can account for this in your future forecasts if you can figure out how inaccurate your previous demand predictions were. You can modify your inventory management practices as needed, such as by boosting safety stock levels to meet unclear demand periods, if you can ascertain how uncertain a forecast is for a specific business period.

You may measure demand forecast accuracy, or forecast error, using a variety of formulas. The mean percentage difference between your actual and anticipated demand during a particular period will be determined by the Mean Absolute Percent Error (MAPE). While the Mean Absolute Deviation (MAD) displays the difference in units between the expected and actual demand.

-

Demand Forecasting Periods and Reviews

Your forecast’s accuracy directly correlates with the time frame you select for your demand forecasting. An inventory demand forecasting for the next two weeks which can be determent by many inventory forecasting tools, for instance, is considerably more effective than one for the next year.

You’ll also need to check your forecasts considerably more in a fast market movement than you would in a slow market movement or for a business with an item’s demand pattern is unstable. You might need to change your forecasting times if you start to encounter stock-outs or notice instances of surplus stock

How To Choose the Right Forecasting Technique?

These techniques are not perfect. Any of them always include some element of luck.

However, by combining any or all of these techniques, you may get your forecasting as near to being error-free as possible. This can help you get a better, more true overview of what has occurred in the past and what may occur in the future.

Let’s take the case where your business produces jewelry. You’ll need to significantly increase your inventory around Christmas, according to forecasted holiday sales.

But which goods will you require the most? Bracelet fashion trends may modify quite rapidly. Previous quantitative and trend statistics aren’t much use in this situation because the “X model” from last year is unlikely to sell out this year.

Therefore, a mixed strategy is usually the best. It presents a clear view, which results in greater insights.

Consequently, you shouldn’t waste your time on strategies that are irrelevant to you or that you know won’t work for you instead use appropriate inventory forecasting tools as needed.

If you’re a brand-new firm, for instance, you won’t have a lot of previous data to apply forecasting inventory based on sales. Due to this, quantitative and seasonal forecasting is difficult.

To acquire a general picture of demand, you can use competitors’ data or data from the larger market. This information won’t be as useful as information from your customers, though.

In this situation, qualitative and trend forecasting needs more of your time and effort. The information you have for this is more significant

Conclusion

Finally, we may state that effective forecasting is a mixture of art and science, and inventory forecasting is an ongoing process with numerous variables influencing the final result. You will have the necessary support to forecast your inventory effectively if you have a solid understanding of the various inventory forecasting methods and techniques. As a result, you will get demand forecasting benefits that will help you to avoid extra costs associated with holding stock and maintain adequate stock to meet the needs of your customers effectively.

Recent Comments