What Is Backordering? And How To Sell More?

Inventory Management

Sell more even if your inventory is out of stock.

With a few strategies, you will sell more even if you don’t have enough products.

It is all about backordering. What does that mean?

What Is Backordering?

Backordering is an order for a product that results in the sale of inventory that is not available at the current time and is not on hand.

Indeed, it is a common practice used by retailers when they are faced with an increase in demand more than they expect. Without any action, you risk losing and disappointing customers and pushing them into the arms of competitors.

How Backordering Works?

Let’s compare two processes to understand how backordering works. The first involves a request for products available in stock while the other involves products that are out of stock.

-

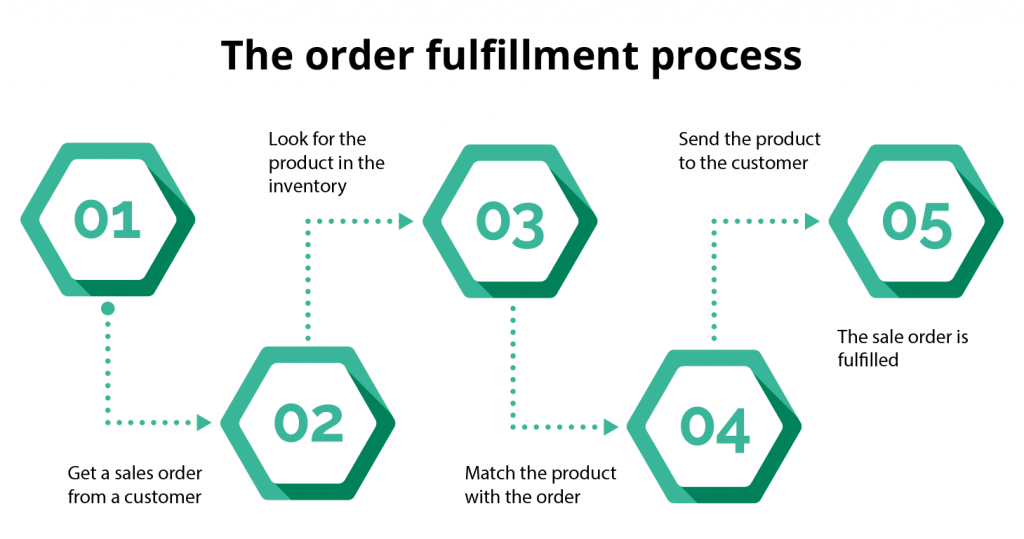

The Order Fulfillment Process Can Be Summarized By The Following Steps:

You get a sales order from a customer. You look for the product in the inventory and match it with the order. After matching, you send the product to the customer and get the sale order fulfilled.

-

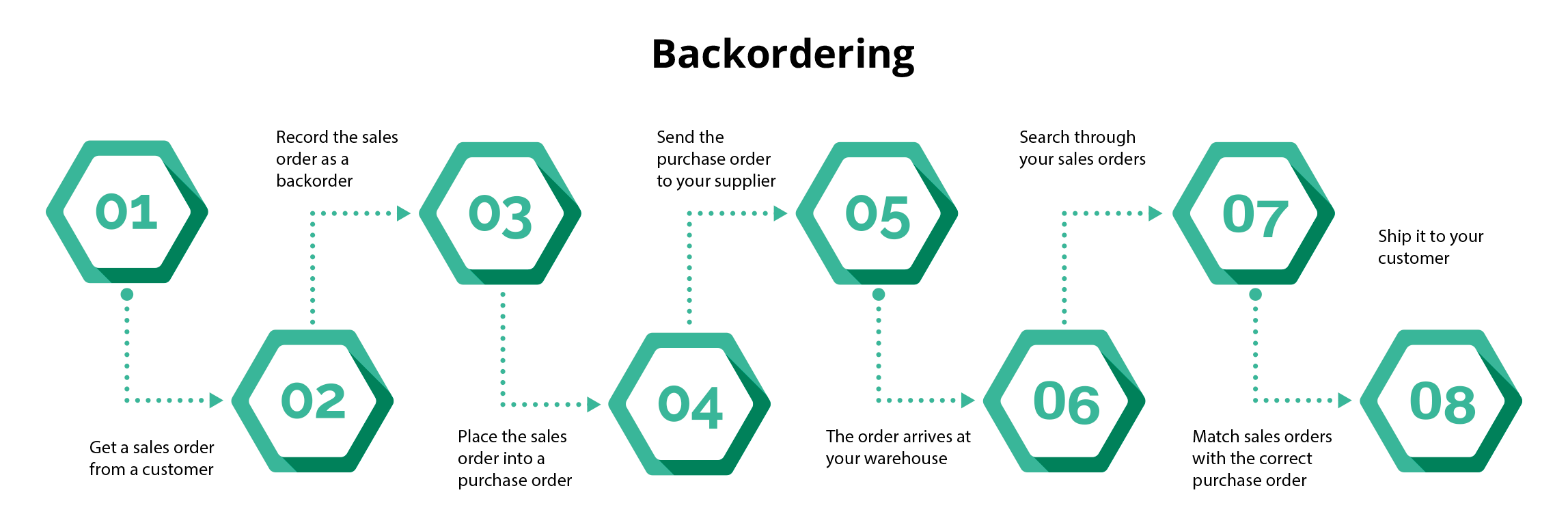

In The Case Of Backordering:

You get a sales order from a customer for a product that is out of stock. You record it as a backorder rather than a completed sales order. Then, you place it into a purchase order and send it to your supplier.

Once your order arrives at your warehouse you search through your sales orders and match them with the correct purchase order. Then, you ship it to your customer and fulfill their order.

How To Manage Backorders?

Using backordering means that the demand for the product is more than the supply, which is a crucial process that may result in a big problem unless it is properly handled.

Look at Amazon‘s experience with Echo devices that were all sold as soon as they were offered, and with the company receiving huge other orders, it registered them as backorders and its customers had to wait for their orders until they were available.

Apple did the same with its iPhone X and made lists of backorders for the phone. The customers had to wait more time to get their devices.

To do it with your business, you have only to apply these points:

-

Planning And Analyzing

Backordering is an essential and important part of the inventory management process.

Companies must develop an organized approach to manage backorders and accurately predict customers’ needs to avoid facing logistical problems or having too many backorders that cannot be fulfilled.

-

Use Inventory Management Systems

When you get a lot of sales orders for unavailable products, it becomes difficult to manage these orders efficiently. Using an inventory management system will save you the hassle of calculating reorder points, creating and merging orders, tracking inventory, and relationships with suppliers before it becomes out of control.

See our amazing inventory management system at the link below:

as well as you can see how New G Solution manages re-order point notifications here.

-

Communicate With Your Customers

Any company may lose its customers if they notice that their orders frequently arrive late, which leads them to cancel orders.

Make sure to communicate continuously with your customers and inform them of all stages of product delivery even if you have logistical problems or delivery delays.

In return, provide some free samples or free delivery to ensure that they will not cancel their orders.

See our integration to keep your customer happy

-

Abandon Untrustworthy Suppliers

Keep a list of trusted suppliers and abandon suppliers who you cannot guarantee their fulfillment of your requests at the right time. Online cloud-based inventory management systems will help you track your orders, relationships with suppliers, and coordinate your order deliveries seamlessly.

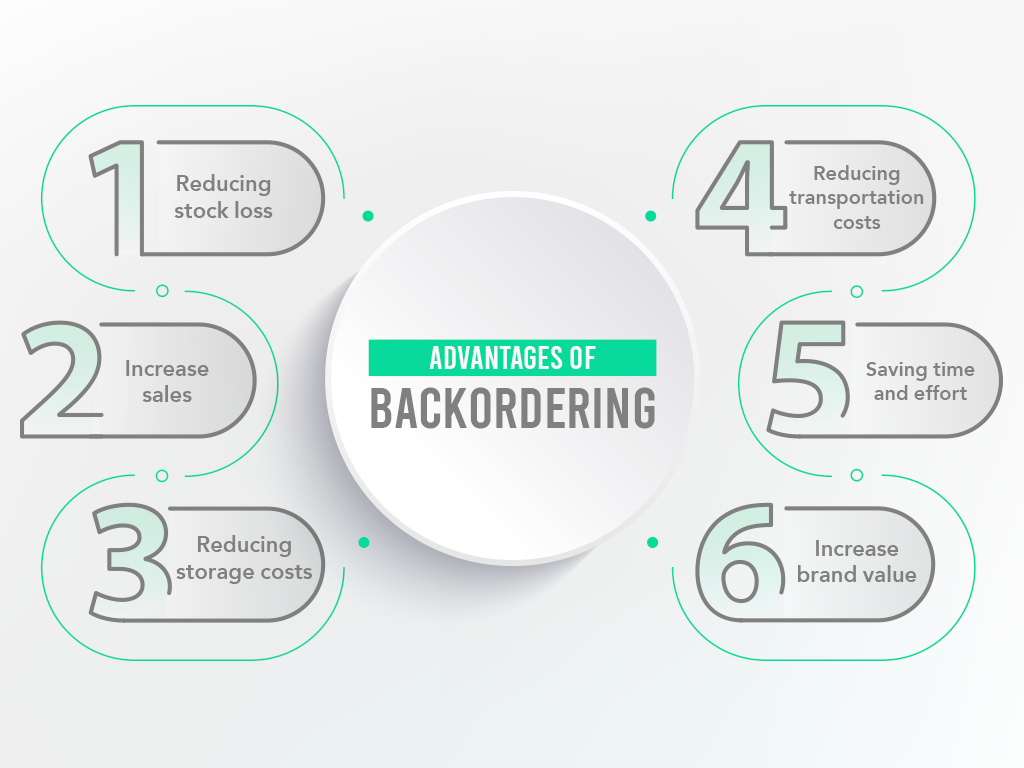

Advantages Of Backordering

1- Reducing Stock Loss

The process of transferring a user’s order directly to the supplier reduces the potential for inventory spoilage resulting from poor stockpiling or extended periods in storage.

2- Increase Profits

The reduction in warehousing and transportation costs reflects on the customers, which leads to an increase in demand. This increases sales, profits, and revenues.

3- Reducing Storage Costs

Backordering relieves the need for warehouses which is required to keep more amount of inventory. This alleviates storage costs.

4- Reducing Transportation Costs

Using backordering will save you a lot of moving products from suppliers and shipping them to customers. You can simply transfer it directly from supplier to customer.

5- Saving Time And Effort

Backordering with an effective inventory management system will help you devise a successful business strategy and save you a lot of time and effort.

6- Increase Brand Value

According to the general rule that says “the bigger the item value, the more delivery tolerance you get from your customer”, some companies use backordering to increase the value of their products in the eyes of the customer as the high number of backorders increases customers’ curiosity and their desire to buy.

Recent Comments