ABC Analysis: The Key to Efficient Stock Control

Inventory Management

LAST UPDATE: MAY 26, 2023

6 minutes reading

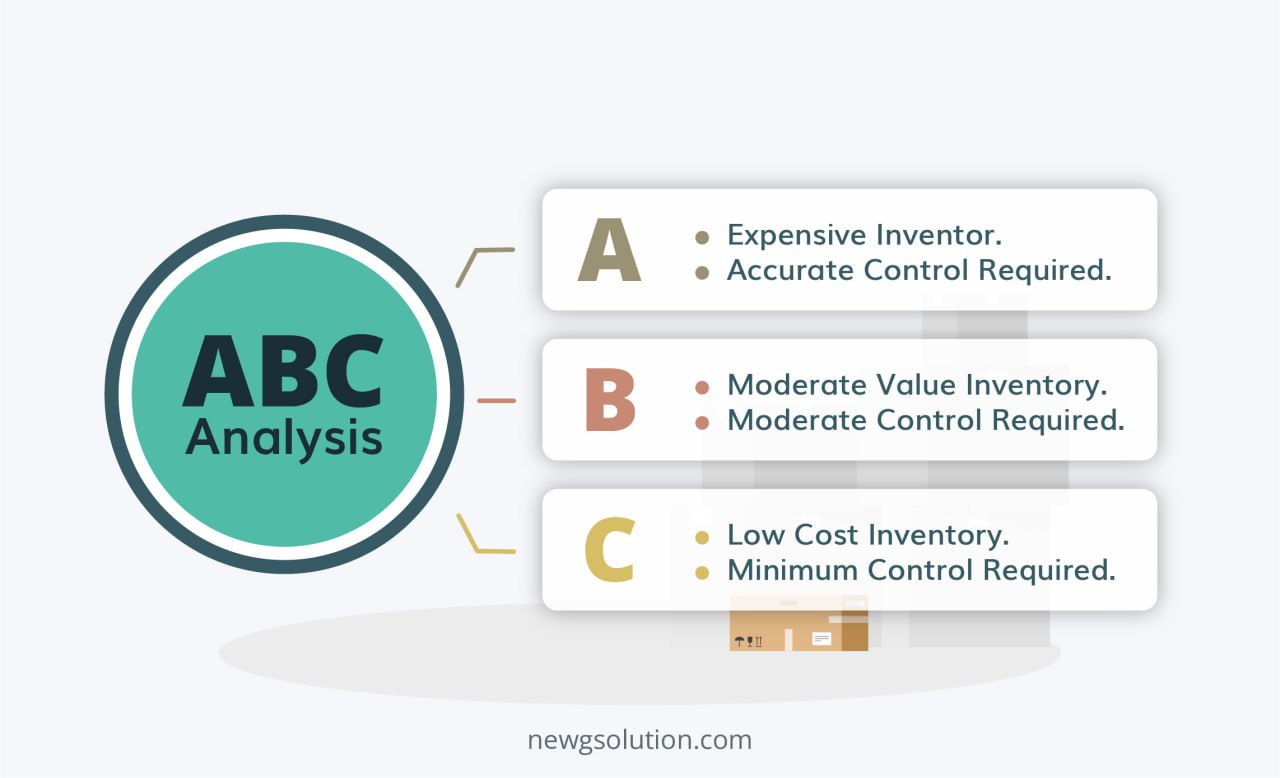

ABC Analysis is a method of inventory management that categorizes items according to their relative importance and usage. The acronym ABC stands for A-items (high-value or high-usage items), B-items (medium-value or medium-usage items), and C-items (low-value or low-usage items). The purpose of ABC Analysis is to optimize the inventory costs and service levels by allocating more resources and attention to the most critical items and less to the less important ones. ABC Analysis can help businesses improve their profitability, cash flow, customer satisfaction, and operational efficiency.

What Is ABC Inventory Analysis?

You may determine which items in your stock have performed the best and worst over a given time frame by conducting an ABC analysis. Better inventory management and earnings are the results of this method’s emphasis on revealing the moneymakers and losers among your company’s products.

The Pareto principle, commonly called the 80/20 rule, serves as the foundation for the ABC classification system used to organize stock.

A Better Understanding of ABC Analysis’ Benefits

- Having tighter oversight of expensive stock can cut down on theft and save money.

- Better utilization of inventory management facilities. The time and money saved by focusing on A-class stocks rather than B- or C-class stocks during a stock count is one example.

- Because of the low value of B and C class assets, businesses can afford to keep larger buffer stocks in case of stock outs.

- Reduced inventory shortages lead to more productive manufacturing.

- Reduced stock-outs and increased productivity translate to a more consistent turnaround time and, in turn, happier customers.

What Are the Steps in Making an ABC Inventory Analysis?

An ABC inventory analysis is a method of categorizing items based on their relative importance and value. It helps to optimize inventory management and reduce costs. The steps in making an ABC inventory analysis are:

- Identify the items to be analyzed and collect data on their annual usage, unit cost, and total value.

- Calculate the percentage of total usage and total value for each item.

- Rank the items in descending order of total value and assign them to one of three categories: A, B, or C. A items are the most valuable and account for a small percentage of total usage but a large percentage of total value. B items are moderately valuable and account for a moderate percentage of both usage and value. C items are the least valuable and account for a large percentage of usage but a small percentage of value.

- Apply different inventory policies and controls for each category based on their importance and value. For example, A items may require more frequent ordering, lower safety stock levels, higher service levels, and tighter quality checks than B or C items.

- Review and update the ABC analysis periodically to reflect changes in demand patterns, costs, or other factors that may affect the inventory performance.

ABC Analysis Formula

ABC analysis is a method of inventory management that categorizes items into three groups based on their value and usage. The formula for ABC analysis is:

(Annual consumption value of item / Total annual consumption value of all items) x 100%

The annual consumption value of an item is calculated by multiplying the unit cost of the item by the annual demand for that item. The total annual consumption value of all items is the sum of the annual consumption values of each item.

The result of the ABC analysis formula is a percentage that indicates how much an item contributes to the total value of inventory. Based on this percentage, items are classified into three groups:

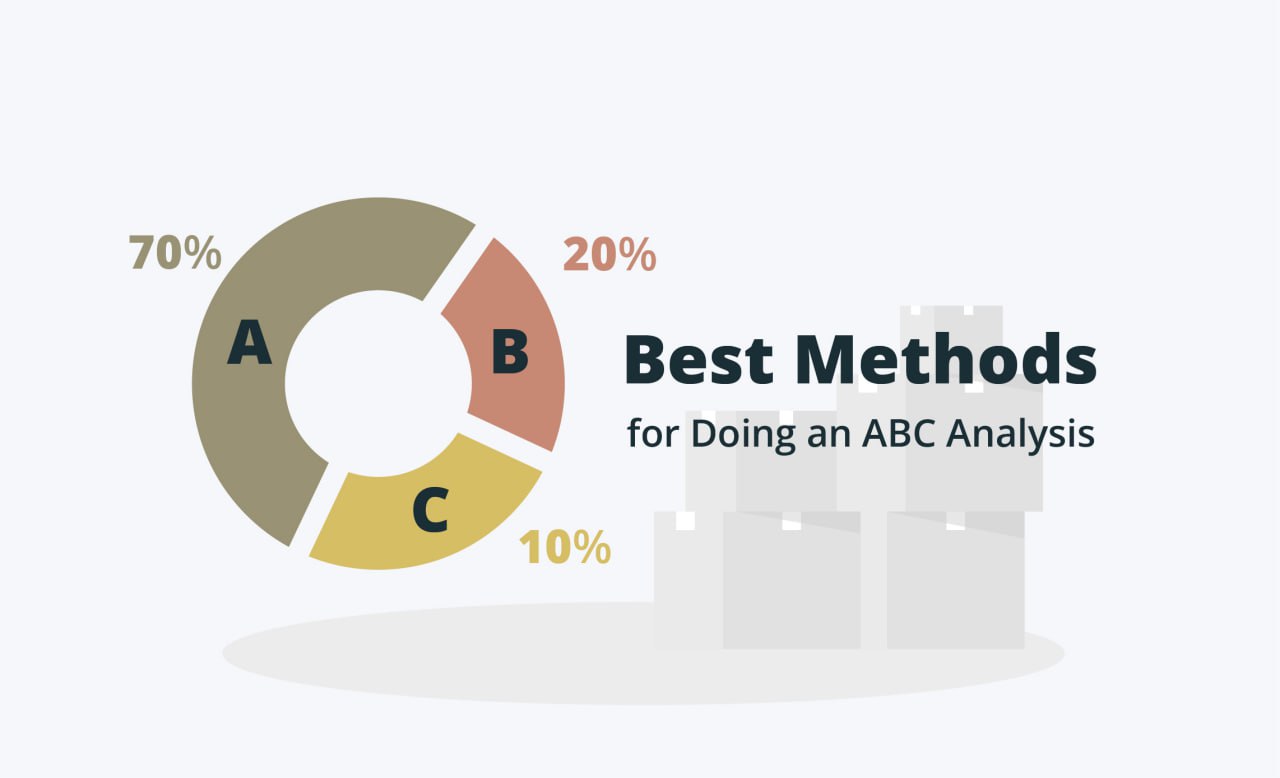

A items: These are the most valuable and frequently used items in inventory. They usually account for 10-20% of the total number of items, but 70-80% of the total value. A items require close monitoring and control to optimize inventory levels and avoid stockouts.

B items: These are the moderately valuable and moderately used items in inventory. They usually account for 20-30% of the total number of items, but 15-25% of the total value. B items require less attention than A items, but more than C items.

C items: These are the least valuable and least used items in inventory. They usually account for 50-60% of the total number of items, but 5-10% of the total value. C items require minimal control and can be ordered in bulk to reduce ordering costs.

In short, ABC analysis formula helps inventory managers prioritize their efforts and resources on managing the most important items in inventory, while reducing costs and inefficiencies associated with less important ones.

Best Methods for Doing an ABC Analysis

ABC inventory management is a method of categorizing inventory items based on their value and importance. The items are classified into three groups: A, B and C. A items are the most valuable and require the most attention and control. B items are moderately valuable and require less attention and control than A items. C items are the least valuable and require the least attention and control.

Some of the best practices for ABC inventory management are:

- Conduct an ABC analysis to identify the value and importance of each item in your inventory. You can use criteria such as annual sales volume, annual sales revenue, profitability, lead time, demand variability or customer satisfaction.

- Assign each item to one of the three categories based on its relative value and importance. You can use a Pareto chart or a cumulative percentage curve to visualize the distribution of your inventory items across the categories.

- Determine the optimal inventory policies for each category based on their characteristics. For example, you can use a higher service level, a lower safety stock and a more frequent replenishment for A items; a moderate service level, a moderate safety stock and a less frequent replenishment for B items; and a lower service level, a higher safety stock and a rare replenishment for C items.

- Monitor and review your ABC inventory management regularly to ensure its effectiveness and efficiency. You can use key performance indicators (KPIs) such as inventory turnover ratio, fill rate, stockout rate or carrying cost to measure your inventory performance. You can also adjust your ABC categories and policies based on changes in demand patterns, market conditions or business objectives.

Optimize Your Inventory With New G Solution

Indeed, ABC inventory analysis is a valuable tool for determining which products perform best and worst so that sales and profits can be maximized. If you want honest evaluations of your stock, you should exclude out seasonal goods and new product lines and consult alternative metrics.

Prioritize Improve the quality of your inventory by spending extensively in it, both in terms of stock levels and in your relationship with your suppliers. Get rid of your grade C stock (and save money on storage) by packaging it with other products, selling it at a discount, or giving it away to those in need.

ABC analysis by product is a breeze to set up in New G Solution. In just a few clicks, it will retrieve sales data to reveal your best (and worst) performing stock.

Recent Comments