Inventory Management KPIs to Improve Business Operations

Inventory Management

LAST UPDATE: AUG 2, 2022

3 minutes reading

Inventory can play a key role in the health of your business; the right management of a company’s stocks affects the business’s flourishing.

likely, using key performance indicators (KPIs) can improve stocks management, inventory tracking, and making better decisions about it.

Inventory management software allows businesses to manage their KPIs efficiently, giving you a look in-depth at your business, as well as evaluating your supply chain performance at different levels of your business.

There are multiple KPIs used to assess the supply chain performance, here are some of them:

Inventory Turnover

It is the most basic business performance indicator; it shows you the number of times inventory has been sold and replaced in a given time period.

This KPI tells you how fast a company is making sales from its inventory.

If the turnover is low, it indicates the company has either weak sales or excess inventory. On the contrary, the high rate shows that the company has strong sales.

Formula:

Inventory turnover rate = Sales / inventory.

Or:

Inventory turnover rate = cost of goods sold / average inventory.

see also Inventory turnover ratio, Explained with Examples.

Days Sales in Inventory (DSI)

This KPI measures the time period that it takes for your inventory to turn into sales.

It is one of the most important metrics that determine the company ability to quickly sell its goods and it reflects the good management of your inventory.

if the number is high, it points to inventory management problems or inefficient sales strategy. On the other hand, the lower the number, the better as it indicates the quick selling of inventory which means, lower inventory storing cost and less time.

Formula:

DSI= (Average Inventory ÷ Cost of Sales) x 365.

see also Inventory days formula, Days Sales In Inventory

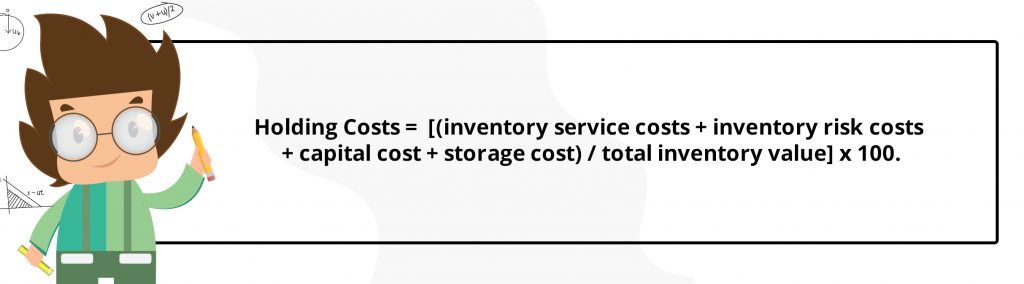

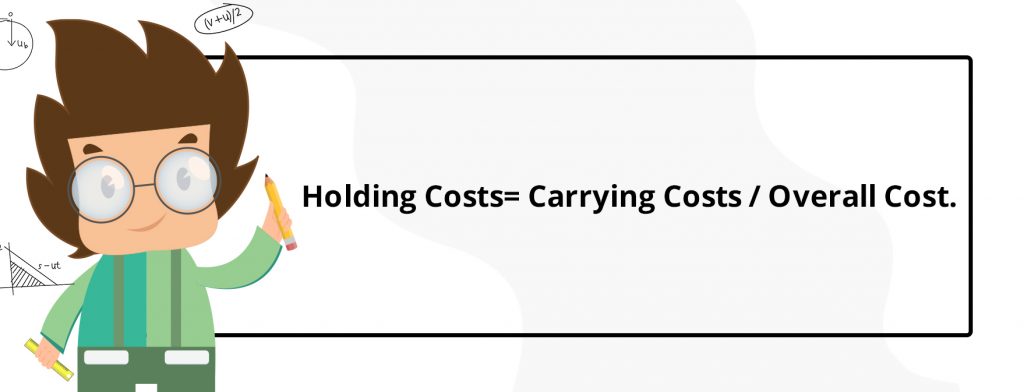

Holding Costs

This KPI measures the cost of storing the unsold inventory, this includes the cost associated with damaged and spoiled goods, in addition to the costs of storage space, labor, insurance, and any unsellable products.

Formula:

Holding Costs = [(inventory service costs + inventory risk costs + capital cost + storage cost) / total inventory value] x 100.

Or:

Holding Costs= Carrying Costs / Overall Cost.

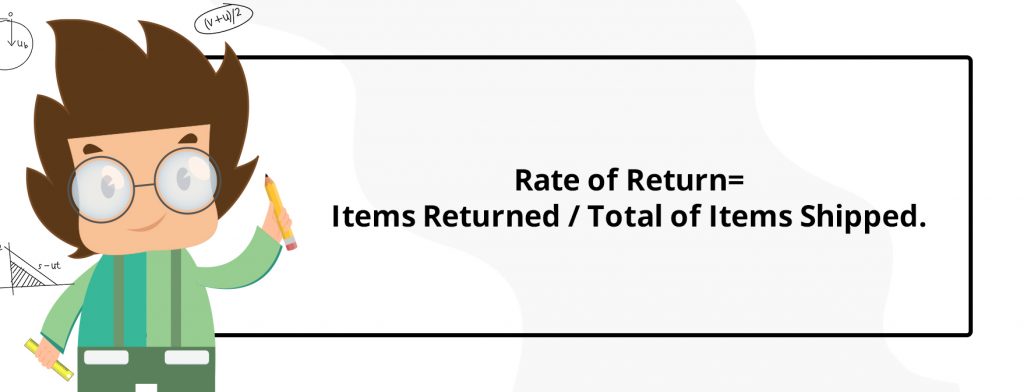

Rate of Return

This KPI measures the percentage of shipped orders that are returned to you and need to be restocked.

this indicator is important to track the reason for the returns to identify any patterns of issues and address any problems in the supply chain.

Formula:

Rate of Return= Items Returned / Total of Items Shipped.

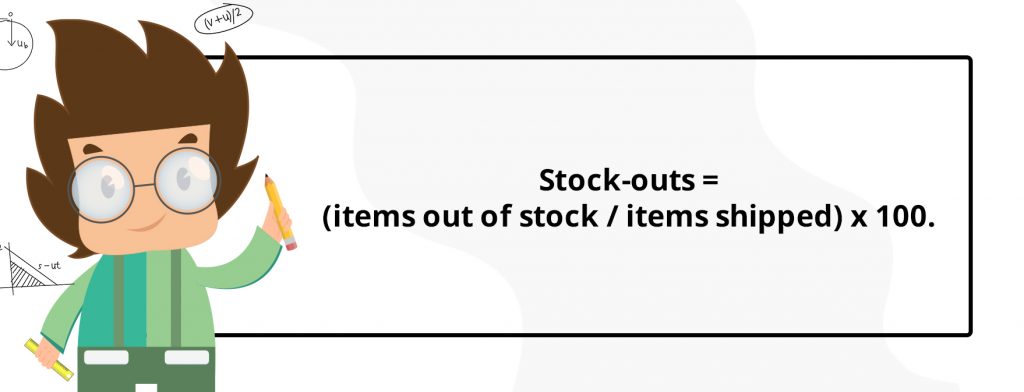

Stock-Outs

This KPI represents the percentage of items not available in inventory when a demand is placed, it measures the number of times demand cannot be met because of the absence of required inventory.

This indicator shows a company ability to meet customer demand, and if not managed in a timely manner, it can cause frustrated clients, missed opportunities, profit losses, and, at last, ruin the reputation of your business.

Formula:

Stock-outs = (items out of stock / items shipped) x 100.

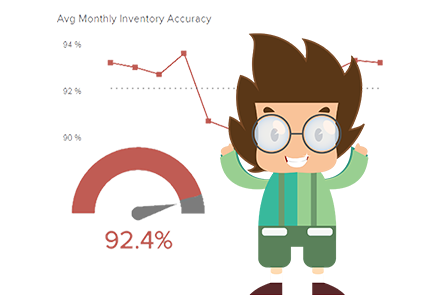

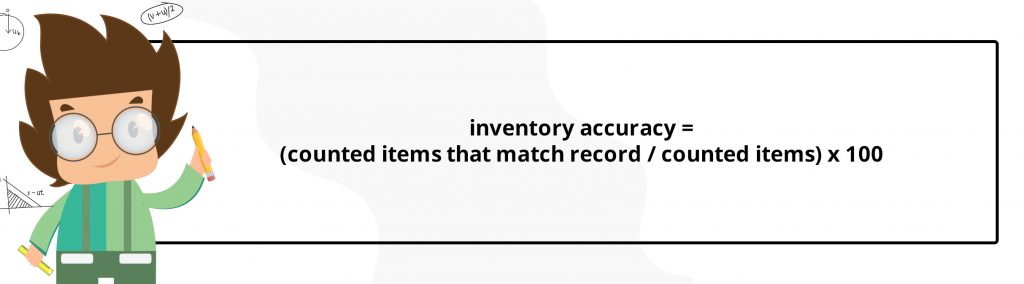

Inventory accuracy

This indicator addresses the matching between official inventory records (databases) and the physical inventory (what is on the shelf for sale).

Having an inaccurate database negatively affects other important KPIs, which in turn, affects the growth rate of your business.

Formula:

inventory accuracy = (counted items that match record / counted items) x 100.

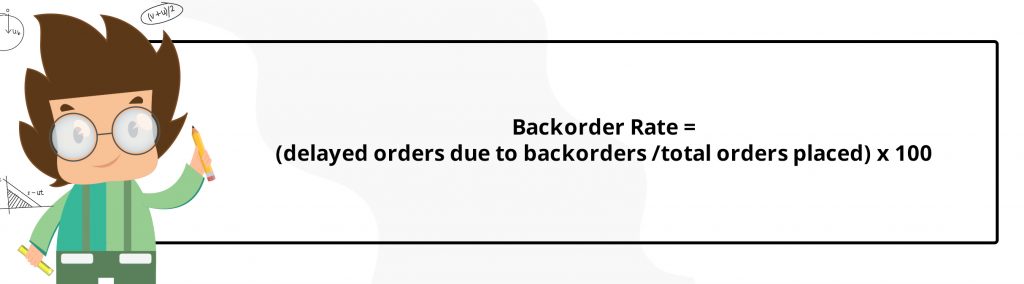

Backorder Rate

it refers to the number of orders a company cannot fulfill when a customer places an order. it clarifies how well you stock your products that customers demand.

Formula:

Backorder Rate = (delayed orders due to backorders / total orders placed) x 100.

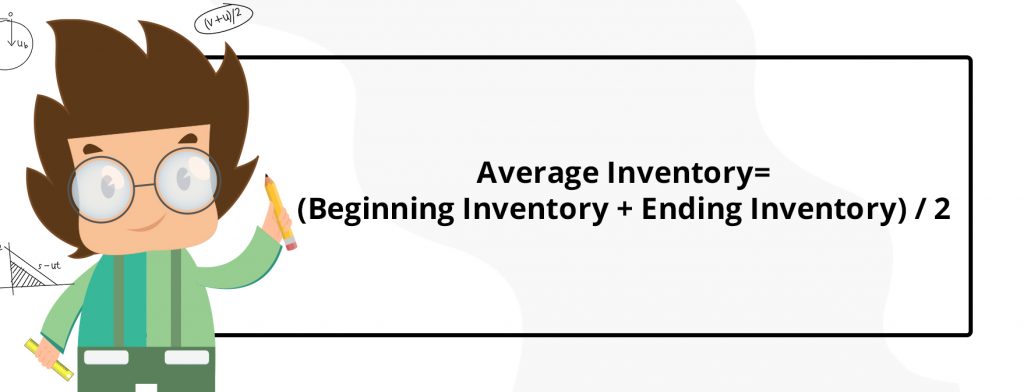

Average Inventory

Average inventory is the amount of inventory a company has on-hand during a specific period of time.

Formula:

Average Inventory= (Beginning Inventory + Ending Inventory) / 2.

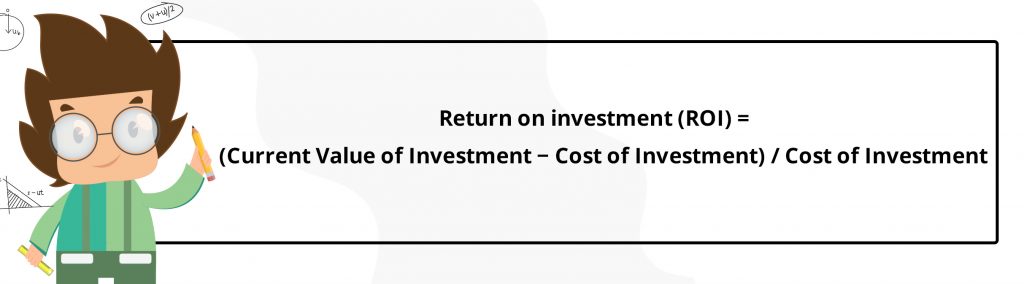

Return on investment

Return on investment (ROI) is a financial metric used to evaluate the profitability of an investment and the gain or loss from an investment relative to its cost.

it evaluates the potential return from an investment or compares returns from several investments.

Formula:

ROI= (Current Value of Investment−Cost of Investment)/ Cost of Investment.

Conclusion

Ultimately, every business has its own model and priorities, make sure you apply the KPIs that fit your business.

A smart Inventory management software can offer you these KPIs to be tracked.

make sure to choose the right system which contains the needed KPIs to track your business performance and lead you to success.

Recent Comments