Optimize Your Inventory with This Ultimate Rule

Inventory Management

LAST UPDATE: NOV 12, 2022

6 minutes reading

It can be challenging to establish streamlined inventory management, particularly if your inventory is dispersed, diverse, and challenging to monitor. Even while inventory management software can handle much of the labour-intensive work, it frequently requires a keen eye to implement strict inventory control guidelines.

According to the 80 20 inventoy rule, 20% of efforts, consumers, or any other unit of measurement produce 80% of the results. The rule says that businesses make about 80% of their revenues on 20% of their inventory when applied to inventories.

Today, we’ll delve into the Pareto law, ABC analysis inventory, the 80 20 inventoy rule, and other methods for optimizing your inventory.

Lower The Costs of Your Inventory

The carrying cost of holding and storing goods for a specific amount of time is what is referred to as the cost of inventory. It is estimated to determine how much a business will benefit. Additionally, it aids in calculating how much more or less inventory you’ll need to meet demand.

What Is The 80 20 Inventory Rule?

The 80/20 inventory rule, Pareto law, or ABC analysis rule can help you gain knowledge on all fronts and manage your product line-up more effectively to improve your balance sheet and possibly boost earnings.

Companies may free up working capital, reduce costs, and boost cash flow by delving deeply into the parameters that go into 80 20 inventory rule calculations.

The 80/20 rule states that 80% of results come from 20% of efforts. The rule says that businesses make about 80% of their revenues on 20% of their inventory when applied to inventories.

With the Pareto law rule, you can enhance sales by identifying those top sellers and putting more emphasis on them than on slower sellers. You can further arrange your inventory to favor higher-margin items within that 20%, which will optimize it for both volume and profitability.

To free up resources for the addition of new SKUs or services, several businesses routinely identify and retire their weakest performers. Others make an effort to correct the situation by altering their inventory and supply chain connections to reduce costs while examining whether these underperformers might increase profit from a marketing expenditure.

Why 80 20 Inventory Rule Is Important?

The majority of CFOs value data-driven approaches to boosting earnings. The statistical research underpinning the 80 20 inventory rule provides decisions makers with a repeatable, verifiable method of managing inventory. The Pareto law rule offers a framework to plan ahead while concentrating your company focus on the most profitable product lines. This is preferable to reacting to client demand or going with the marketing teams gut feeling.

Inventory Analysis in Excel

Consider yourself managing inventories at a facility that produces luxury, extremely expensive autos. There are many pieces (4,693 to be exact) needed to put each car together. Some of these components cost thousands of dollars each, while others are inexpensive (50 cents per part). How can you then ensure that your inventory tracking efforts are streamlined such that you spend more time on expensive items and less time on parts that cost 50 cents each?

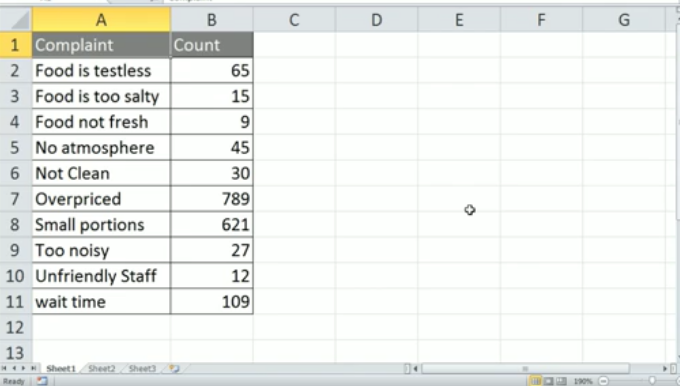

ABC Analysis Inventory Examples in Excel

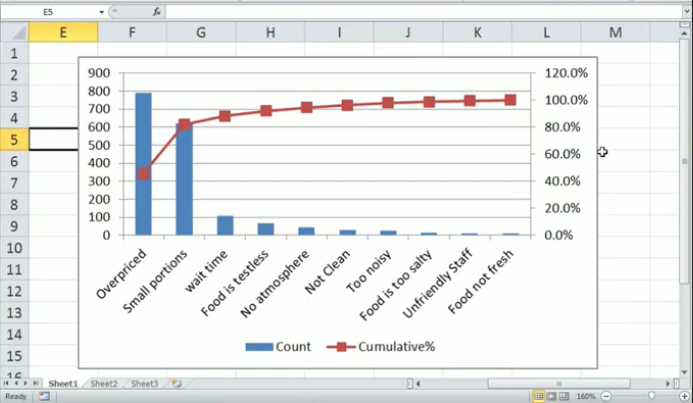

You may learn how to make Pareto analysis in excel by following this example. According to the Pareto principle, 20% of causes account for about 80% of the effects of many events.

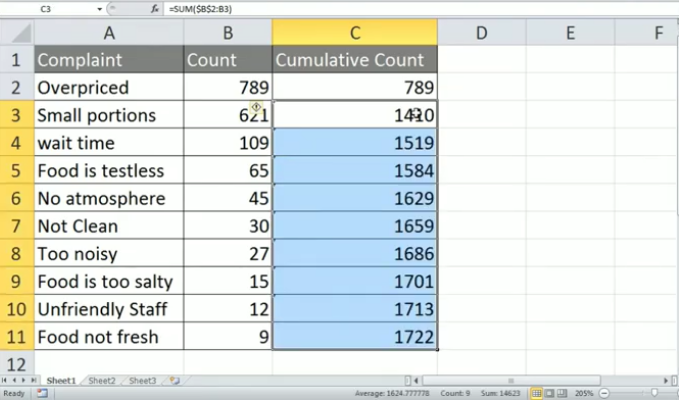

- First, pick a digit from column B.

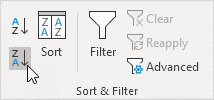

- Next, sort your data in descending order. On the Data tab, in the Sort & Filter group, click ZA.

- Calculate the cumulative count. Enter the formula shown below into cell C3 and drag the formula down.

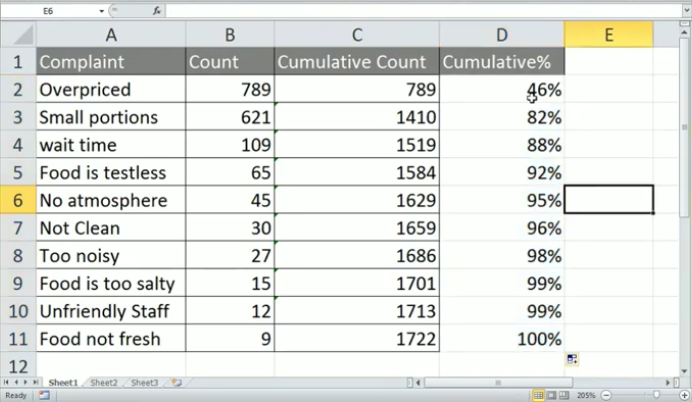

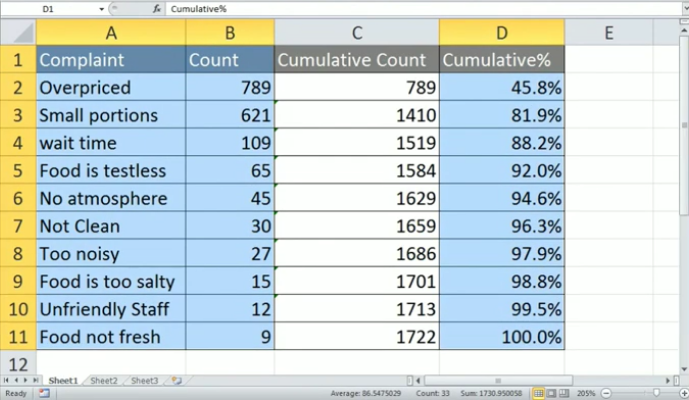

- Calculate the cumulative %. Enter the formula shown below into cell D4 and drag the formula down.

Note: cell C11 contains the total number of complaints. When we drag this formula down, the absolute reference ($C$11) stays the same, while the relative reference (C4) changes to C5, C6, C7, etc.

- Select the data in columns A, B, and D. To achieve this, hold down CTRL and select each range.

- On the Insert tab, in the Charts group, click the Column symbol.

- Click Clustered Column.

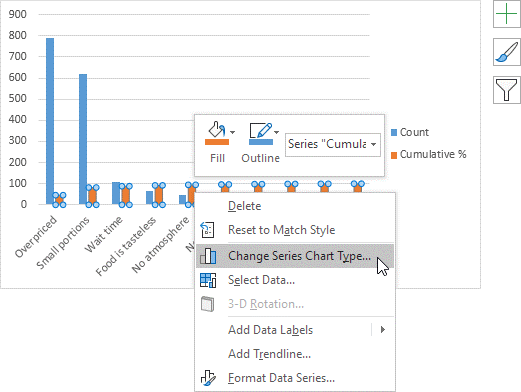

- Right-click on the orange bars (Cumulative %) and click Change Series Chart Type…

- For the Cumulative % series, choose Line with Markers as the chart type

- Plot the Cumulative % series on the secondary axis.

11. Click OK

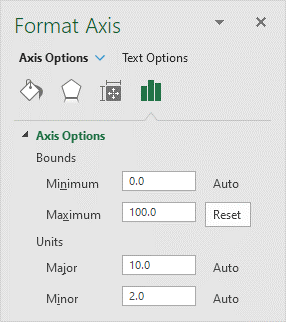

- Right-click the percentages on the chart, click Format Axis, and set the Maximum to 100.

Result

How to Implement the 80 20 Inventory Rule

The 80/20 inventory rule need not be a difficult concept to adopt. In fact, getting started is a simple procedure with the correct software and equipment.

Software for inventory management should be used

If you don’t currently have a system for managing your inventory that can provide you the insights you need, start by selecting specialized software or checking to see if your ERP provider has inventory management modules. Because you can more readily include financial and other data in reports, it may be a more efficient option than a standalone inventory management system.

Determine the top 20% of your best-selling and most successful products.

Although there will probably be some overlap, these two lists might not quite line up. Then, create a list of products that result in high sales volumes and increase profits utilizing your inventory or ERP system. The two work well together to create a successful product. Additionally, as was mentioned, determine which SKUs are most likely to join that top 20% soon.

Analyze And Improve Your Inventory Management

Start making changes to your operations to improve the fit between inventory and demand once you have a list of your top 20%. Inventory control, also known as stock control, professionals ensure that the appropriate kind and quantity of supplies are available at the appropriate time to meet consumer demand.

Refresh your marketing

Now that you are aware of your most lucrative products, you could want to focus more on promoting those SKUs. Bestsellers might not require further marketing, whereas very successful products outside the top 20% might require more expenditure than less successful ones. Consider which products in the bottom 20% could be dropped without having an impact on customer satisfaction.

Monitor And Iterate

It is not possible to set the 80 20 inventory rule and forget about it. Keep an eye on the performance of the best items, then analyze the information you’ve gathered to tweak your procedures over time. Experts in inventory forecasting should be consulted, particularly when supply networks and customer demand are undergoing fast change. These experts concentrate on statistical data analysis and can forecast which goods might get to the top tier.

Manage your Inventory with New G Solution

The ideal inventory solution, New G Solution, puts you in control. By seamlessly integrating with various systems, managing your stock, and synchronizing all of your warehouse activities, it gives you complete control over your inventory. Contact us

Conclusion

Even while not all businesses maintain inventories, almost all businesses can increase profit from a study that reveals which products or services generate the highest profits. Don’t stop there though. You will discover more applications for the 80/20 rule in your organization if you begin viewing everything through that lens.

Recent Comments