Full Guide About Bullwhip Effect

Supply Chain Management

LAST UPDATE: Feb 25, 2023

10 minutes reading

If the bullwhip effect has never occurred to you, consider yourself lucky. It can make it difficult to meet consumer demand, chew through profits, and undermine your efforts to manage your supplier relationships. Lack of knowledge of how supply and demand affect your inventory control and management process is a major contributing factor to the issue.

Read more about the bullwhip effect causes and solutions, its causes, and ways to prevent or mitigate it by reading on.

What Is the Bullwhip Effect?

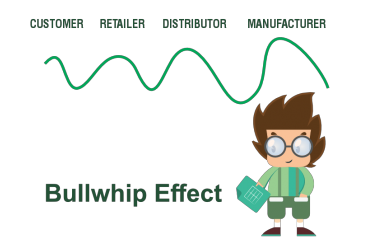

Demand shifts at the end of a supply chain can cause inventory swings further down the chain, a phenomenon known as “The Bullwhip Effect”. Typically, small changes in demand at the consumer or retailer level propagate up the chain and result in larger differences.

As a result, supplies are either purchased in excess or insufficiently at each link in the supply chain. These goods frequently become out-of-stock, require backorders, or must have significant price reductions to prevent complete loss.

Bullwhip Effect Example

Let’s break down this information with a few examples if it all sounds a little complicated:

Assume you are a wholesaler of food and you consistently sell 1,000 tuna cans to a client each week. Then, this client orders twice as much tuna as they usually do. Assuming that demand is rising, you buy 2,000 cans to avoid running out. As a result of your increasing purchases, your supplier might stockpile more tuna, aggravating the problem even more.

On the other end of the spectrum, having insufficient supplies can cause problems. Let’s assume that, in the aforementioned example, you didn’t raise the quantity of tuna you buy. On the other hand, customer demand remained on the rise. You would immediately encounter a problem satisfying demand. Then you put a bigger order with your supplier, who is likewise unable to match the demand, which causes a shortage of tuna cans.

You can see how overreacting to demand changes can lead to issues throughout the supply chain, even though these are incredibly simplified instances.

Causes of the Bullwhip Effect

The supply chain’s many linkages and tiers frequently react similarly. If they observe a disparity in orders or supplies, they often change their statistics accordingly. As a result, if one level commits an error, it may negatively affect all other levels.

The following situations can result in the bullwhip effect:

- Lack of Customer Information: A variety of events, including natural catastrophes, major world events, shipping problems, and misunderstandings, can skew news regarding supply chain patterns. Supply chain professionals may not have the most up-to-date information available when making judgments if these circumstances hinder communication. Making decisions based on erroneous data can cause professionals to experience the bullwhip effect.

- Inexact Lead Time: The lead time refers to how long manufacturers anticipate it will take to assemble and ship products. Lead times that are longer than the trend window at hand may result in an increase in supply during periods of low demand.

for instance, a product might be extremely popular for one month. The units are less likely to sell if retailers don’t stock their shelves with them until two months have passed. Manufacturers risk missing the window of opportunity and creating the bullwhip effect if they make erroneous lead-time predictions.

- Automated Commands: Organizations risk overestimating consumer demand if they place orders through automated processes or in large quantities. Automating orders may lead to an oversupply or a decrease in demand.

- Discounts or price adjustments: The bullwhip effect can also result from price adjustments and discounts. Demand may increase if a vendor offers a discount on a product. The lower price may cause buyers to behave differently and cause sellers to place excessive stock orders as a result.

How the Bullwhip Effect Impacts the Supply Chain

The bullwhip effect has a large impact on supply chain management and has the following effects:

- Storage Expenses

- Expanded Labor

- Unfulfilled Client Expectations

- Waste

Storage Expenses

Overstock is expensive to purchase. You must cover the costs of the actual storage space, the inefficiency of keeping commodities that may not be in great demand any longer, the cost of shipping the goods, and the cost of selling them, which may be expensive if you have to offer discounts to entice customers to buy them. The bullwhip effect also makes it harder to forecast your shipment and storage expenses.

Expanded Labor

To handle, organize, and sell additional products that you have on hand, you must pay personnel. Similarly, salespeople may need to put in more effort to find alternatives or schedule later delivery if a seller runs out of goods. These labor needs may accumulate.

Unfulfilled Client Expectations

Your reputation and revenue may suffer if you run out of a product. Being unable to offer products might annoy your clients, make you appear less dependable, and even prompt some of them to search for new partners or brands. This is true whether you’re trying to satisfy the demands of consumers or other supply chain participants.

Waste

Depending on the product you work with, having too much inventory can result in expensive waste. Consumable commodities like meals and medicines, for example, could expire before you can sell off your supply, while other products might be taken off the market or replaced by newer models. These occurrences may decrease the value of the objects, increase the number of resources needed to sell them, or increase the cost of an item that must be thrown away.

Also Read: Best Strategies to Improve Supply Chain Efficiency

How to Control the Bullwhip Effect

The bullwhip effect can be reduced to a minimum to guarantee more predictable and successful supply chain management. The bullwhip effect can be caused by a variety of factors, but it can also be fixed in several ways. Listed below are some suggestions for minimizing the bullwhip effect.

1- Boost Communication Between Customers and Suppliers

Because supply chain participants don’t fully understand the reasons why consumers are raising demand, the bullwhip effect intensifies. Everyone may better understand the context of demand shifts by increasing visibility throughout the chain.

Are more orders being placed as a result of a discount, seasonal demand, or another factor? Members can identify potential overreaction triggers and address them before the situation spirals out of control.

Below are several useful tools:

Electronic Data Interchange (EDI): With the use of EDI, business partners such as suppliers, clients, carriers, and third-party logistics (3PL) providers can exchange documents in real-time. Ordering, providing shipment notifications, and invoicing are just a few of the many functions that EDI systems may automate and optimize.

Vendor Managed Inventory (VMI): Suppliers can get real-time sales and forecast information from their downstream partners’ thanks to VMI initiatives. The data is evaluated by a machine-learning algorithm along with predetermined settings like min/max shelf presence to produce replenishment recommendations. Suppliers can place new orders without waiting for retailers or distributors to run out or run low using VMI.

Internet of Things (IoT): A rapidly expanding field of supply chain management is IoT. Real-time data regarding stock counts and product locations can be obtained through sensors that are connected to your system. Greater openness on the part of the organization may also mean greater openness among supply chain partners. Other predictive advantages include the ability to foresee problems and upkeep requirements that can impair operations or product quality.

Supplier Enablement portals: Supplier enablement portals allow suppliers and buyers to interact effectively and uniformly even without EDI. Both those who use and those who do not utilize EDI solutions can easily integrate with each other’s systems thanks to portals’ support for web EDI interfaces and EDI solutions.

2- Begin Predicting

To understand demand shifts better, projections must be made with care. You can gather information on almost every aspect of your company’s operations and transform that information into insightful recommendations for preventing the bullwhip effect using the large variety of intelligent inventory software currently available.

Advanced algorithms and calculations are used in predictive analytics to analyze historical trends and present-day events, and estimate future trends. These systems might be basic or complicated, many of them utilizing artificial intelligence (AI), but they all depend on reliable data.

3- Cooperation between partners should be encouraged

To prevent experiencing the bullwhip effect, various supply chain participants must cooperate. Sharing information is crucial in this situation because it enables organizations to work together and see the entire supply chain rather than just the portion they control. Collaboration is crucial in supply chains that are becoming more globally interconnected, as goods may travel across borders and pass-through numerous companies.

4- Reduce Lead Times

Long lead times can make the bullwhip effect worse by causing things to arrive far later than they are required and turn into overstock. Bullwhip problems can be reduced by shortening lead times everywhere and scheduling orders when demand is high.

Depending on your company’s needs, the factors affecting lead times will change. However, some techniques to cut lead times include:

- Using Reliable Local Vendors

Getting the product closer to its destination can cut lead times and expenses. Finding trustworthy, quick partners is always possible, even though this option isn’t always a good choice.

- Purchasing VMI

Real-time data can be used to accelerate restocking instead of waiting for new orders, greatly reducing or perhaps eliminating the amount of time shelves are empty.

- A Logistics Manager Is Hired

You can increase the level of monitoring and focus on inventory management with a team member devoted to logistics. They should ideally shorten your lead times and assist with other aspects of the bullwhip effect.

- Reviewing Your Shipping Procedures

Check your shipping alternatives if lengthy lead times or unpredictable deliveries are a concern for you. See whether this choice would be feasible for you if one of your partners offers air shipping but prefers to ship internationally via boat. The benefits of more predictable inventories may outweigh additional expenditures.

- Manufacturing Automation

On the manufacturing side, you could be able to provide shorter lead times if you have automated machinery and software that makes the process more effective.

5- Reduce Or Deal with Price Fluctuations

If you routinely provide discounts or promotions, you might be upsetting customary buying patterns and making it harder to forecast demand. Consider your position on these promotions and whether there may be more disruptions than benefits. It’s possible that you don’t need to eliminate them, but you should think about reducing them or accurately factoring them into your projections and predictions.

FAQs

Why Is It Called Bullwhip?

The physics of a whip crack inspired the name of the effect. The very slight movement of the person holding the whip snapping their wrist causes the wave patterns to progressively get louder.

What Increases the Bullwhip Effect?

The bullwhip effect may typically be increased by slight variations in demand, but there are other frequently occurring causes as well:

Complicated supply chain

The supply chain can get more complex by adding a sales channel, more SKUs, or even operating out of multiple warehouses (without the proper technology to manage a network). This is true even if there is visibility across the board.

Miscommunication

The bullwhip effect can happen when several parties involved in a supply chain fail to communicate about manufacturing problems, demand changes, transportation delays, or other crucial supply chain elements.

Cost Variations

The disruption of customer demand trends by discounts, sales, inflation, and other promotional activities can result in erroneous inventory forecasts.

When merchants discontinue their sales or promotions or raise prices to fight inflation, it might become troublesome as suppliers grow accustomed to receiving large amounts of orders.

Customers Demand

As was already mentioned, consumer demand has the potential to both complicate the supply chain and produce the bullwhip effect.

It can be challenging to effectively estimate and refill inventory due to unforeseen variations in customer demand caused by seasonality, developing trends, and other external variables.

Recent Comments