The Full Guide About Multi-Warehousing

Inventory Management

LAST UPDATE: NOV 14 , 2022

13 minutes reading

The need for a new warehouse is a sign that business is booming! But there are a lot of what if as well. If you’re concerned about managing inventory across multi-Warehousing, we have put up a summary of everything you need to know to grow your e-commerce or 3PL company successfully.

- What if a new warehousing causes my flawless fulfillment process to falter?

- What if I don’t have adequate knowledge of best practices for warehousing managment and having numerous warehouses overwhelms me?

- another “what if” for you. What happens if you don’t make the appropriate adjustments and your company finds it difficult to meet demand? At best, your business will remain modest. At worst, you end up losing money and endanger the reputation of your business.

What Is the Concept of Warehousing?

The act of holding tangible inventory for eventual sale of distribution is known as warehousing. All various kinds of businesses utilize warehouses when they need to temporarily keep goods in large quantities before sending them either individually to customers or other locations.

For instance, a lot of e-commerce companies buy goods in bulk from their suppliers, who then send them to their warehouses for storage. The company, or its third-party fulfillment provider, selects and packs the item from the warehouse and ships it straight to the consumer once the end user puts an order on the eCommerce site.

For more clarification let’s use the example of an online business that specializes in bridesmaid dresses. Your warehouse is in Florida, and historically, your target market has been in the Southern US. To meet the demands of a rapidly growing customer base, you added facilities in Texas and California this year.

Since you now have to oversee many warehouses, you must Control your inventory levels and keep tabs on what products clients are ordering from different regions of the nation. Your work in multi-warehouse management will include a significant amount of understanding and managing these choices.

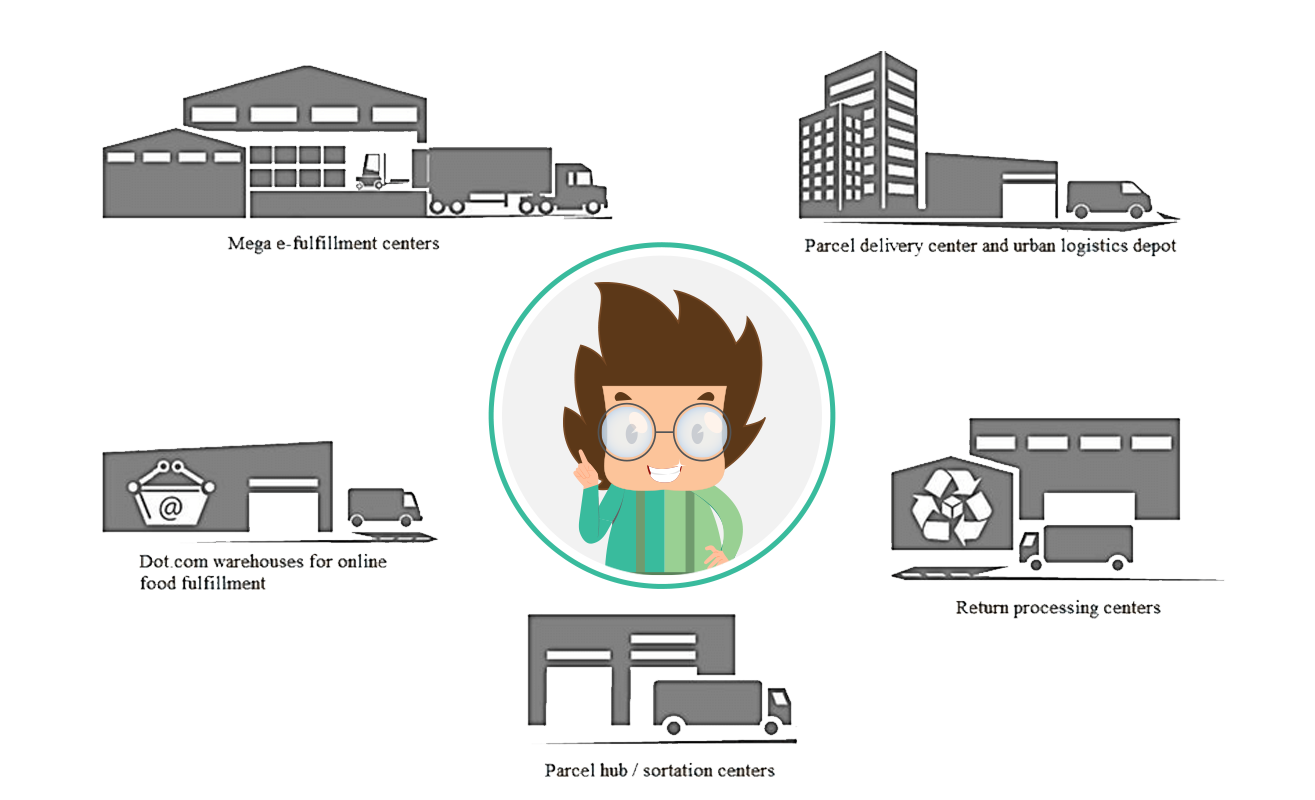

Type of Warehouses

There are three different kinds of warehouses, as follows:

Private Warehouses:

Large manufacturers and retailers own and run private warehouses to meet their storage demands. Due to the significant investment required to build a warehouse, most businessmen are unable to use the products they manufacture or buy. However, some large corporations that regularly require extensive storage space and who have the financial means to do so, build and maintain their private warehouses. A large manufacturer or wholesaler could have a nationwide network of its warehouses.

Public Warehouses:

A specialized business establishment known as a public warehouse offers storage space to the general public for a fee. It could be owned and run by a single person or a cooperative group. It must operate with a government license and in line with the established norms and regulations.

The government is promoting the construction of public warehouses in the cooperative sector since they are crucial to the marketing of agricultural products. A duty-paid warehouse is another name for a public warehouse.

For the business community, public warehouses are highly helpful. Due to the significant financial investment required, the majority of business enterprises cannot afford to operate their warehouses. In many circumstances, the storage needs of a commercial organization do not justify the upkeep of a private warehouse. These businesses don’t need to make large investments to use public warehouses to meet their storage demands easily and affordably.

Bonded Warehouses

Government-issued permits allow bonded warehouses to accept imported commodities for storage until customs duty is paid. They’re situated close to the ports. Either the government or customs authorities are in charge of running these warehouses.

The warehouse must guarantee or “Bond” that it won’t let the removal of the items without the approval of the customs authorities. It is not possible to remove the products from the bond without first paying the customs charge. Without the approval of customs officials, the owner is not permitted to intervene with the products kept in bonded warehouses. Hence the name bonded warehouse.

He is not required to pay customs duty if he intends to export the products. Additionally, a bonded warehouse offers all of the services offered by public warehouses. A bonded warehouse allows for the packaging, grading, and branding of goods for sale.

What Are the Main Functions of Warehousing?

1. Storage

This is the fundamental purpose of warehousing. In warehouses, surplus goods that aren’t immediately needed might be kept. They can be given to customers when they require them.

2. Price Stabilization

In the process of stabilizing prices, warehouses are crucial. It is done by generating time utility through warehousing. It is avoided for product prices to decrease during times of abundant supply and to increase during times of shortage.

3. Risk Breaking

When products are kept in warehouses, they run the risk of being stolen, damaged, discovered, burned, etc. These risks are minimized through the design of warehouses. When the items are kept in wave houses, the bailment contract is in effect.

Both the person holding the items in the warehouses and the warehouse manager serve as the boiler. A warehouse keeper is required to protect the items from various threats and take reasonable care of them. The warehouse keeper is responsible to the owner of the commodities for any loss or damage to the goods.

4. Financing

The owner’s items in storage may be pledged as collateral for loans obtained from the warehouse keeper. For the warehouse manager, the items serve as security. In a similar vein, banks and other financial organizations make loans secured by warehouse receipts. In this way, storage serves as a source of funding for businessmen to carry out their daily activities.

5. Grading And Packings

These days, warehouses offer tools for packaging, processing, and grading products. Depending on the owner’s instructions, the owner can pack the goods in practical proportions.

What is Multi-Warehousing Management

The management of operations across several warehouses is referred to as multi-warehouse management. The phrase refers to all activities that involve personnel, inventory, shipping, storage, and movement of commodities.

Multi-Warehouse Management is used more specifically in the context of e-commerce, where it refers to the logistics involved in delivering and fulfilling orders from various warehouses. There are numerous reasons why an online shop may ship from different warehouses.

Also, you can read more details on Multichannel Sales can be found Here.

Benefits of Multi-Warehouse Management

It is inherently less expensive and quicker to transport to a larger area when there is a multi-warehouse. However, the advantages go far beyond this. There are numerous more advantages to using a system that efficiently controls warehouse distribution, which will improve order fulfillments accuracy, efficiency, and transparency.

- One Single Point of Truth

- Countless Warehouses

- Live Information

- Locate And Monitor Stock Moves in The Warehouse

- Transfers Of Warehouse Inventory

One Single Point of Truth

You have a dependable, ongoing supply of correct information about each of your warehouses and what is inside them when you have good multi-warehouse management. As a result, there is no longer a requirement for individual warehouse management, which might result in information becoming segregated inside a certain area.

With multi-warehouse management, all of the data related to each of your warehouses are indexed and readily available. This eliminates the requirement to connect various warehouse information across disparate platforms.

When multi-warehouse management is used, common problems with over and understocks, inconsistent inventory levels, and missed fulfillment dates are eliminated. Say goodbye to confusion, frustration, and inaccuracies, and get acquainted with a single point of truth.

Countless Warehouses

You can have as many warehouses or fulfillment centers as you require, regardless of how big or small your firm is. Adding and customizing warehouse data is simple with effective multi-warehouse management, and the system takes over from there.

The capacity to fulfill orders based on specific order details is the most important feature that your management system must have among the many features and options you may need. To put it another way, for your warehouse management system to be efficient, it must effectively connect with your e-commerce platform. A clever method enables seamless connections between each order placed and each item of inventory required to complete the order.

Live Information

The ability to obtain real-time, reliable data is the most important benefit of multi-warehouse management. Inventory and distribution function smoothly when every warehouse employs the same system.

It’s crucial to upload and sync all data precisely while setting up your warehouse management so that everything may proceed with assurance. With precise information readily available, you can keep an eye on stock levels and merchandise in transit as well as updates and changes within each warehouse. Even better, regardless of where the fulfillment warehouse is located, you will be able to obtain order data in real-time if multi-warehouse management is properly configured.

Locate And Monitor Stock Moves in The Warehouse

There is no longer any ambiguity surrounding current stock levels, order statuses, or fulfillment logic because there is complete visibility into every order and every item of inventory. As a result, you get a single perspective of each warehouse and everything inside, providing you with complete freedom to complete orders in the most effective manner. Finally, you have total visibility into every product’s location.

Transfers Of Warehouse Inventory

Transparent systems with good multi-warehouse management provide unmistakable insight into necessary stock transfers. You’ll have complete control to transfer stock for prompt order fulfillment because you’ll have real-time information on specific stock levels and order volume. The system is promptly updated after an order is picked, removing problematic inconsistencies and delays.

6 Justifications for Distributing Your Inventory Among Many Warehouses

The first step on the road to diversifying your inventory is to take quick action. To expand your consumer base and keep your most devoted customers happy, you must be flexible as a business owner or operator. Diversifying your inventory across several warehouses is one of the best methods to demonstrate your flexibility. The top 7 reasons to use this strategy in your business are listed below.

1. Fast Delivery Times

The primary benefit of using multi-warehousing is accelerated delivery times. Fast delivery times are essential, whether your customers are medical device manufacturers whose products must be used immediately to save lives or college students who need their personalized school supplies yesterday. A fantastic strategy to speed up delivery is to store your product in various warehouse sites close to important subsets of your consumer base.

2. Crisis Preparation

The coronavirus COVID-19 outbreak serves as a reminder of the benefits of using various warehouses. Many producers shipping from a single location were unable to get their products into the hands of customers due to mandatory traffic reductions in some jurisdictions and the shutdown of businesses considered non-essential in other areas. However, businesses that had more than one warehouse site been able to reach more clients.

Natural catastrophes can hinder a company that runs out of a single warehouse. If you have inventory in San Francisco and Detroit, for instance, you can continue to fill orders even if a hurricane and flooding hit your South Florida business.

3. Lower Shipping Costs

You may conveniently ship from the warehouse that is nearest to your customer because your goods is carefully housed at numerous safe warehouse locations. With this agreement, your products can be delivered to clients more quickly without having to pay more for expedited shipping.

4. Access That Is Easier for Client Visits and Pickups

You can have customers that would like to organize their own pickup and delivery depending on the nature of your business. Additionally, you can get queries from potential distributors who want to look at your stock and business practices before opting to buy from you.

It is simpler for potential customers to directly view your inventory and how you prepare orders for transport if you have various warehouse sites. This is crucial for overseas clients who want to verify a supplier’s validity and inventory availability in person before making a purchase.

5. Create a Surface for Growth

Utilizing several warehouses makes it possible for your expanding organization to expand. Working together with a reputable 3PL provider who can manage your inventory and logistics while you concentrate on expanding your business can help you to accomplish this aim. The best part about this technique is that it enables your business to grow both geographically and in terms of order fulfillment.

6. Client Satisfaction

An eco-friendly strategy, cheaper shipping, and quicker delivery dates all work together to promote consumer happiness. A multi-warehousing approach might soon emerge as the most effective weapon in your company’s toolbox because higher levels of customer satisfaction frequently translate to recurring business.

Tips on Managing Multiple Warehouses Effectively

Be Careful to Synchronize

Integration of your online businesses, physical stores, POS system, and inventory system with real-time synchronization between them is the solution to this issue. Ideally, the stock level would be immediately updated in real-time across all channels whenever a customer purchases a product through any of the channels that you have integrated into the system. This aids in preventing sales of previously out-of-stock goods in addition to preventing inventory shortages.

Increase The ROI Of Your Inventory by Using Analytics

Poor inventory control has unintended effects on ROI. And when you have poorly managed multi-warehouse management, those effects are substantially worse. Retail inventory reports allow business owners to pinpoint exactly what needs to change in order to maximize the ROI on their inventory.

Keep An Eye on Your Warehouses at All Times

There is always room for unforeseen events when you have a well-designed multi-warehousing inventory and a real-time synchronization system.

Even so, it’s still possible that you’ll run out of popular things, particularly during peak times like holidays or shipping days like black Friday. And having different warehouses makes everything even more challenging

Utilize Reports to Improve Multi-Warehousing Management Planning

There is always space for improvement, so make the most of your multi-warehouse inventory management in POS to find those areas and determine how to enhance your inventory to be more cost-effective and organized.

What Role Can New G Solution Play?

By designating the warehouse where you wish to receive your purchase orders, you can have a full warehouse management experience of your inventory across various storage locations.

You can use the New G Solution to accurately count the inventory in each warehouse and to make each warehouse’s inventory dependent on the demands of the clients who are closest to the warehouse. So, you can ship the merchandise to clients faster and lower the cost of labor and shipping, making them happier. Contact us

Conclusion

Ecommerce retailers must take a number of factors into account when they decide to expand to more than one warehouse. Any retailer would be wise to put in place a potent multi-warehouse management system that transforms every order into a useful piece of data if the objective is expansion with a strategic plan for management.

Recent Comments