Your Guide to Lot Number

Inventory Management

LAST UPDATE: JAN 4, 2023

9 minutes reading

Many of the items we use on a daily basis, including food, beverages, transportation, toiletries, and medications, have lot numbers.

Generally, the codes assist manufacturers in identifying information about their products, such as which materials were used to build them, where they came from when they were made, and if they are perishable when they will expire. Different companies assign lot number in different ways.

Here, we’ll examine the significance of lot number and how they benefit businesses.

What is Lot Number?

A lot number is a special designation that producers use to identify a batch of products they made in the same run using the same components, parts, or resources.

Does The Batch Number Match the Lot Number?

Yes. Numerous other terms, such as batch number (most commonly used in the UK), code number, or lot code, are frequently used to refer to lot numbers.

What Is Lot Number Tracking?

The lot tracking system is used to track, trace, and retrieve data about the products from beginning to end of your supply chain. Barcode Scanners, and inventory management software are used to do this.

If you create and bottle ketchup, for instance, a monitoring system will show you the lifetime of each bottle, including the sources of the ingredients. Once it has been sent, you may follow its route from your manufacturing facility through the warehouse and all the way to your clients.

Why Is Lot Tracking Used?

Regulatory bodies in various industries, like the pharmaceutical and medical supply industries, mandate the usage of lot batch tracking. This might make it easier to recall products owing to food safety concerns. Other times, lots are utilized to improve inventory control and warehouse productivity.

It allows for comprehensive reporting of shelf life and keeps track of sell-by dates. Additionally, lot tracking makes FIFO (first-in, first-out) warehousing simpler.

Examples Of Items That Are Typically Assigned Lot Number

Yes, lot numbers are frequently applied to items with expiration dates. For instance, medical supplies or vitamins and supplements. However, lot numbers serve more purposes than simply archiving information on goods that have expired.

Lot numbers excel when used to store information about a product for a particular point in time. Of course, this aids in keeping track of expiration dates, but it may also and frequently be used to provide specific information on shelf life or in first-in, first-out (FIFO) accounting.

Other inventory products that typically have lot numbers include the following:

- Fire Extinguishers and Batteries

- Household Detergents and Cleaners

- Mobile Devices and Other Electronics

- Supplements And Vitamins

- Medical Equipment

What is Lot control?

The technique of managing your batches of items and goods is known as lot control. It gives you the ability to organize them, monitor their performance, identify any potential problems, and move them around as needed. For instance, you could have to redistribute or recall a batch of products.

It will eventually enable you to discover trends surrounding certain products and suppliers as well as vital information like how long they remain on the shelf.

The Importance of Lot Control Number

When a product has a problem, Lot control becomes very important (we’ll explore this further later). Apart from emergencies, Lot control is essential for sustainability and preserving a competitive edge in the complicated business environment of today.

- Stay Organized

- Identify Issues Quickly

- Reveal Trends

- Prevent Counterfeit Products

Stay Organized

First off, the procedure keeps you organized by making it simpler to distinguish between comparable goods with minor differences, such as a standard and sugar-free soft drink or two batches of t-shirts created with various color dyes.

Identify Issues Quickly

In addition, Lot control enables you to immediately identify problems with materials or parts, operators who require additional training, or machinery that needs maintenance when one of your items has a flaw. You’ll be in a better position to choose the appropriate course of action to address the situation if you can identify the root of the issue.

Reveal Trends

Thirdly, by revealing trends like which batch of products are selling the most (and at what time of year), and whether there is any connection between the suppliers you’ve used and your most profitable items, Lot control can offer insightful business information.

Prevent Counterfeit Products

Finally, Lot control can assist you in preventing the entry of counterfeit goods into your inventory. Tracking your lots will help you figure out where fakes are entering your supply chain if your items are prone to them, allowing you to take action to stop more from entering.

While some companies still manage their lots by hand, automation and analytics are becoming increasingly important, especially in complex supply chains where there is a higher risk of human error. If you don’t already have it, it’s worthwhile to check into high-quality software that will work for your company. Remember that a lot of inventory and supply chain management software will come with built-in lot control features.

Lot Number Tracking Best Practices

Here are some best practices to implement in your inventory management in order to fully benefit from lot tracking.

- Lot Adherence

- Fulfillment By Lot

- First In, First Out Strategy

- Quick Expiration Date Strategy

Lot Adherence

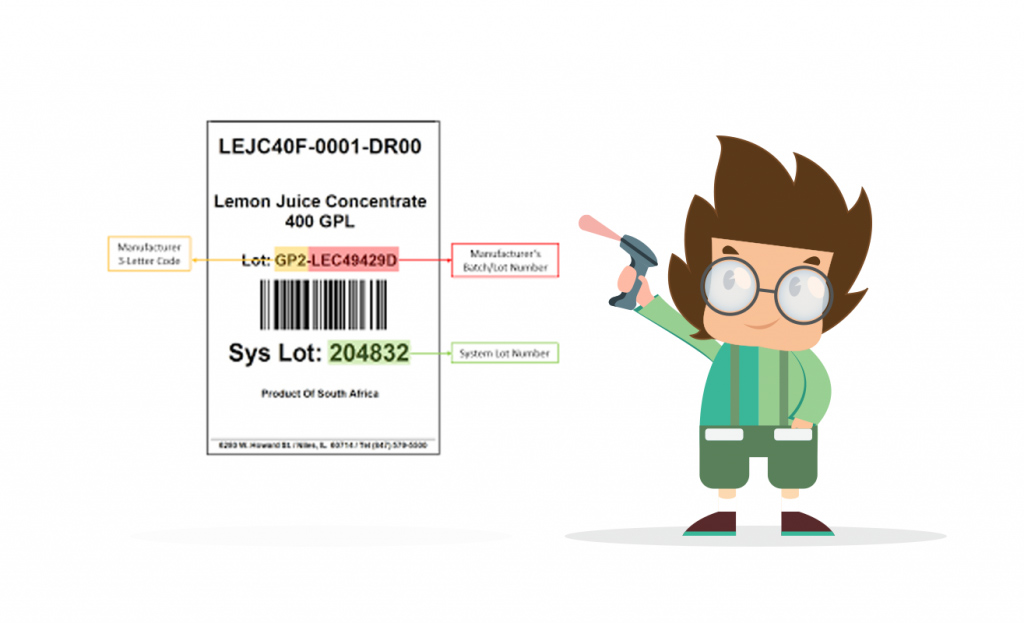

This entails tracking inventories by lot number rather than merely stock keeping unit. The package should display lot batch numbers as a visible print, a scannable barcode, or both. Barcodes on lots should be readable by inventory systems. Include this information in your overall inventory management plan.

Fulfillment By Lot

It’s crucial to fulfill orders at the lot level throughout processing in order to maintain inventory information current. This includes accurately classifying and matching inventory products from the right lot that need to be fulfilled. The best-by dates are honored thanks to this practice. Software or services for order fulfillment can automate this procedure.

First In, First Out Strategy

According to the principle of “First In, First Out,” the products you get first are sent out first. This is crucial for products that have a use-by date. Additionally, as time passes, the likelihood of an object becoming out of style or becoming obsolete rises. This can be used in inventory value in both accounting and warehouse management. Your financial statements are more precise when inventory valuation processes are enhanced. Lot no tracking is required for the process to work.

Quick Expiration Date Strategy

The identification of products with limited shelf life or that are about to expire helps with lot no tracking. You may provide discounts on items that are about to expire since you want to ship these items as soon as possible.

What Should You Consider When Creating Traceability Lot Codes?

Make sure the traceability lot codes on your items are not located on the portion that customers throw away, chop off, etc. If you’re the type of person who doesn’t eat their chips in one sitting, you might want to do a few tests. For example, chip bags frequently have the date printed directly at the top, which might be rubbed out after a few rolls up and down.

Make sure that typical, everyday use, like opening, closing, and storage, won’t make your lot code harder to understand. It is crucial that a product has some durability, especially for those that reach the final user.

If your production process involves multiple steps, each one will produce a unique lot code that will be consumed by the following step. You can isolate particular issues when conducting a recall thanks to the step-by-step division into various lot codes, which also lowers the financial risk to your company.

Stock Keeping Units (SKUs) vs. Lot Numbers /Differences/

Both are utilized for tracking, tracing, and object identification. An SKU, on the other hand, specifies a specific kind of item with characteristics that set it apart from similar items. Manufacturer, description, material, size, choices, version, color, packing, and warranty conditions are a few examples of product qualities. Typically, a warehouse or corporation counts the quantity of each product when taking inventory.

Product codes are retailer-specific codes that can be used to calculate inventory stock and identify items on an e-commerce store using a hand scanner or equivalent barcoding technology. A lot can be used to track any inventory batch at a certain moment in the interim.

What’s The Difference Between Lot Batch Numbers Vs. Serial Numbers?

Products can be identified and tracked using serial numbers as well as lot batch numbers. Each SN, however, is specific to a single product even if multiple things may share the exact same lot. It’s similar to how various first names are given to family members who share the same last name.

We can demonstrate the differences between these identifying numbers using the example of laptop devices. The lot number on a batch of laptops may all be the same, designating a date of shipping or completion of manufacturing. Next, every laptop has a distinct serial number of its own. The last option is to give computers a product code that may be used to identify all laptops of the same color, model, and manufacturer.

Simplify the Task of Tracking Lot Numbers and/or Serial

Lot tracking software can be a standalone tool, a built-in feature to inventory management software (like New G Solution), or part of a warehouse management system.

This helps with proper inventory management for batches of the same product that can’t risk being mixed (i.e., foods or beverages that might be recalled in the event of a contamination scare). Lot tracking software helps you see where and how many units of the same SKU are stored so you can easily retrieve them, know which product was sent where, and help you send out the oldest product first (with the most-nearing expiration date).

The first in, first out (FIFO) inventory allocation logic employed by New G Solution is also designed to identify shelves containing products with an expiration date first and always ship the items with the closest expiring lot date first. We will always ship the bin that has been updated with a lot date if you have items stored in two different bins, one without a lot date and one with one. Contact us

Recent Comments